CNC, or Personal computer Numerical Command, encompasses the manufacturing system in which machines Slash, carve and kind components based on Laptop codes that Manage the cutting Instrument’s velocity and motion.

In relation to machining centers, there are numerous sorts of machine centers that cater to unique manufacturing desires. A person prevalent type could be the Vertical Machining Center (VMC), which has a vertical spindle axis. This layout allows for easy accessibility and loading of workpieces from previously mentioned.

In essence, the Instrument changer is a significant element that contributes to maximizing the capabilities of a CNC machining center, which makes it an indispensable asset in contemporary manufacturing processes.

Inside CNC There are 2 primary file formats that impact the CNC machining course of action. Most folks have heard of G-code, which might be Employed in the two CNC and 3D printing, but M-codes are also crucial.

Modern day machining centers usually include things like an computerized door operation system that provides quick access to the operate location. This attribute adds benefit and safety, allowing operators to load and unload workpieces easily, with no have to manually open up and close hefty doors.

The new ROBODRILL Plus delivers a wide array of advantages concerning pace, efficiency, simplicity of use and automation. From the vertical machining center arena, it’s definitely a activity changer for organizations seeking To maximise efficiency and continue to be aggressive.

One particular key benefit of HMCs is their power to work on a number of sides of a component with no need to have for repositioning, as a result of their horizontal orientation.

Very similar in variety to CNC mills, CNC drills make use of a spindle and drill but rather than forming a part, in its place only cut holes. These holes may be exactly made for dimensions, diameter, and depth.

A machining center comprises numerous intricate parts, Every single serving a particular perform in the overall procedure. We’ll delve to the technical descriptions and features of these vital parts.

Tedious: Boring is utilized to enlarge present holes with high precision. Unlike drilling, which results in a gap, dull fine-tunes the diameter to precise tolerances. Boring will also be used to suitable any misalignment in the opening, guaranteeing that it's properly cylindrical.

The enhanced number of motion that 5-axis machining centers provide permits complex areas for being machined in a single set up, cutting down cycle periods and improving upon precision. This would make them ideal for industries for instance aerospace, automotive, and medical equipment where by intricate geometries are prevalent.

As technology carries on to advance, machining centers will likely Engage in an far more sizeable position in shaping the future of manufacturing, emphasizing the need for qualified operators and steady innovation.

We have tested a lot more than a dozen of the most well-liked CNC together with other machines to assist you to choose the very best get more info router for yourself, and our purpose is to be by far the most informative CNC web page on the net.

Numerical Control machines are managed by numerical Guidance referred to as packages. These are definitely fed into your machine by means of punch cards, demanding proficient operators to watch and use. NC machine applications are difficult to modify, as an example if problems arise.

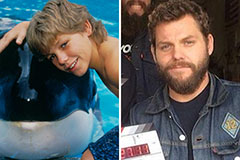

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now!